Terms and definitions of timber doors:

- Timber Door: It is a wooden door, including its frame product made of wooden materials (plank, lumber, synthetic wood, etc.) mainly.

- Lumber: It is a wooden square or plank sawn from logs, generally used to make solid wood furniture and veneer wood.

- Veneer: It is made of sawn wood by planing and cutting in different ways, generally 0.6 mm and 0.2 mm. Low-grade timber door is generally 0.2mm.

- Coating: Also known as lacquer, it can be divided into water solubility and agent solubility. Water-soluble paint is commonly referred to as water-based paint, and agent-soluble paint is also commonly known as paint.

Classification of timber door surface workmanship (painting):

- Water Coating: It is a kind of wooden ornament coated with water thinner and organic solvent-free, free of benzene, toluene, xylene, formaldehyde, free TDI toxic heavy metals, etc. It is non-toxic and nonirritating, harmless to the human body, and does not pollute the environment. The paint film is full, crystal clear, flexible, and has the characteristics of water resistance, wear resistance, aging resistance, yellowing resistance, fast drying, and easy use.

- Painting: General varieties include PU polyurethane, PE unsaturated resin, NC nitrocellulose paint, UV ultraviolet light curing paint, etc. Polyurethane paint is one of the most widely used paint varieties for interior decoration at present. Its film is tough, with strong adhesion, wear resistance, water resistance, chemical corrosion resistance, light retention, color retention, and other excellent film properties.

- Open paint/Sealing paint: It is the effect of paint. The former can see the wood grain and pores, while the latter can’t. There are totally enclosed, semi-enclosed, and other types.

- Color paint/Clear paint: It is classified according to whether the paint has color. The former refers to the paint surface that can cover the original base course. It has a lot of color choices and does not have high requirements for base materials. The latter is a transparent paint effect, and the original color and wood grain of the coated surface can be seen. Clear paint has high requirements for woodworking, and the selected materials are very particular.

- Matte paint/Gloss paint: The gloss of paint can be classified into the following grades: super matte, matte, eggshell (soft), mercerized (satin), semi-matte, and high gloss (bright). Its glossiness is from low to high, and the grades are based on the degree of reflection of light. In oily paint, there are three kinds matte, semi-matte, and high gloss. There is no grade difference among the three kinds of gloss, but they are used in different places, such as doors and windows, and furniture, where matte or semi-matte is often used, while high gloss is generally used for floors because the general hardness of high gloss is also correspondingly high. In water-based paint (emulsion paint), almost all the gloss is available.

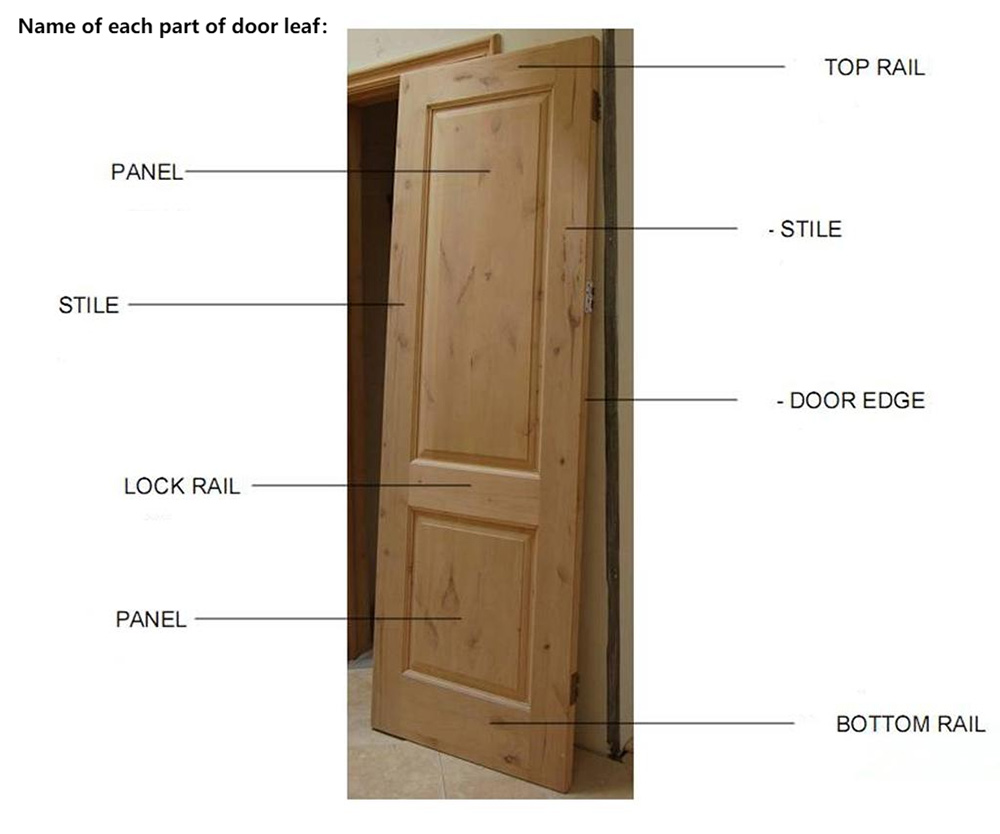

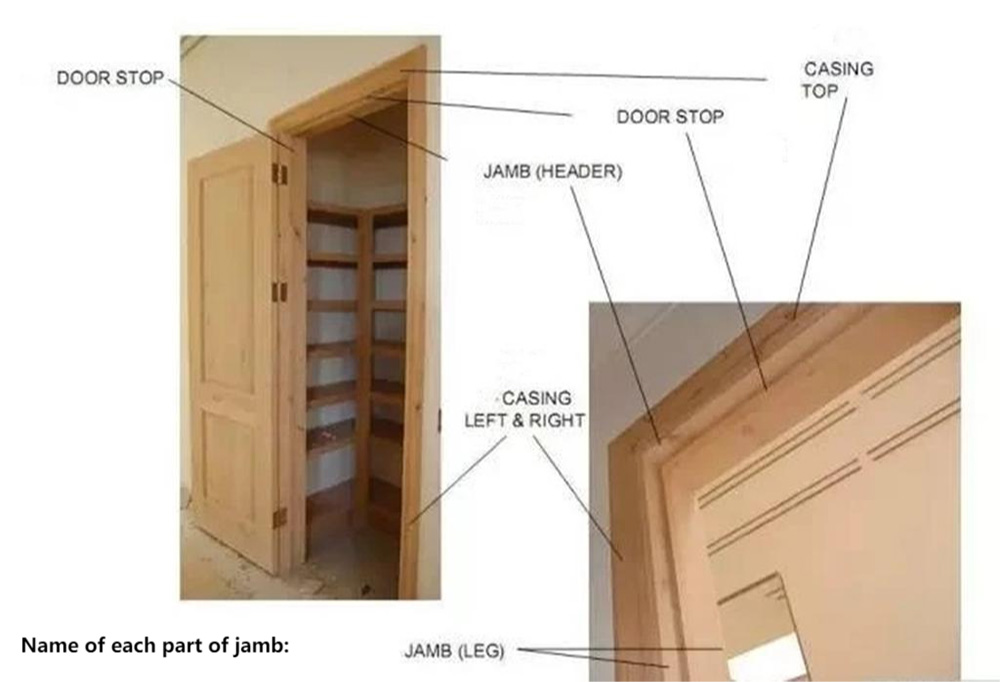

Components, internal structure, and classification of timber doors:

- Components of timber door: The timber door is generally composed of a rail, a stile, and a panel. But now, because of the design needs, many doors have broken the conventions, so it can not be detailed to tell.

- The internal structure of timber door: Generally speaking, the structure of a solid wood composite door refers to the structure of the stile. At present, there are mainly the following structures:

LVL/China Fir Finger joint wood +(MDF+Veneer)/Lumber

LVL/China Fir Finger joint wood +(MDF+Veneer)/Lumber Chipboard/Veneer

Chipboard/Veneer

Honeycomb paper + MDF +veneer/plywood

- Classification of timber doors:

- Classified by opening mode: Timber doors can be divided into four types according to the opening mode: vertically hinged door, sliding door, folding door, and swing door.

- Classified by internal structure: According to the different structures of timber doors, timber doors can be divided into solid doors, laminate doors, and mold doors.

- Solid door: Timber door with completely unified external and internal materials. It generally refers to all types of timber doors with this feature, including half-glass doors and glass doors made of solid wood. The drying of wood is the key process of making solid wood doors.

- Laminate door: It refers to all kinds of solid core doors made of wood, man-made board, micro veneer, and other materials, and generally refers to all timber doors with this characteristic. It is an effective means of comprehensive utilization of wood, which is produced under the situation of increasingly scarce forest resources and increasingly prominent contradiction between the supply and demand of precious tree species. The use of veneer technology is the most prominent feature of laminate doors.

- Mold door: This is a hollow door(the unsupported area is above 10cm*10cm) made of plywood and wood as the skeleton material, and the surface layer is made of man-made board or PVC board by pressing or molding.

- Classified by external appearance: According to the appearance, we generally divide timber doors into plane doors, panel doors, etc.

- Classified by surface coating:

- Paint door: the door whose surface is the spray painting process.

- Paint-free door: the door doesn’t paint. The surface materials are generally PVC, Boeing film (imitation of the strong wooden paste mold), and melamine (melamine decorative paper).

- Baking varnish door: Baking varnish is actually a surface technology, and the base material is a density board. The baking varnish door is classified as piano baking varnish and metal baking varnish.

Common wood varieties and characteristics:

- Sapele

Its scientific name is Entandrophragma cylindricum, commonly known as phantom wood. Found in tropical Africa. The wood grain is interlaced, sometimes with a wavy texture. The grain has a sense of glitter and is three-dimensional, giving people a sense of luxury and elegance. The red-brown color can render the festive and warm atmosphere of the decoration place.

Its scientific name is Entandrophragma cylindricum, commonly known as phantom wood. Found in tropical Africa. The wood grain is interlaced, sometimes with a wavy texture. The grain has a sense of glitter and is three-dimensional, giving people a sense of luxury and elegance. The red-brown color can render the festive and warm atmosphere of the decoration place. - Cherry

It is distributed in various areas of the eastern United States. The heartwood color of cherry wood changes from bright red to brownish red and becomes darker after being exposed to the sun. Cherry wood has fine and even straight lines, and smooth grain and naturally contains brown tree heart spots and small gum pits. Generally used for high-grade interior decoration materials.

It is distributed in various areas of the eastern United States. The heartwood color of cherry wood changes from bright red to brownish red and becomes darker after being exposed to the sun. Cherry wood has fine and even straight lines, and smooth grain and naturally contains brown tree heart spots and small gum pits. Generally used for high-grade interior decoration materials. - Teak

It is distributed in some countries in Southeast Asia, and there are some in China near the border of Yunnan. Among them, Thailand and Myanmar are the most famous. This species is mainly imported from Myanmar. It has a golden luster. The best one is made in Thailand. The teak is oily and bright, with uniform color and straight grain. It is corrosion-resistant, wear-resistant, shiny as new, has beautiful patterns, elegant and durable colors, good stability, and small deformation.

It is distributed in some countries in Southeast Asia, and there are some in China near the border of Yunnan. Among them, Thailand and Myanmar are the most famous. This species is mainly imported from Myanmar. It has a golden luster. The best one is made in Thailand. The teak is oily and bright, with uniform color and straight grain. It is corrosion-resistant, wear-resistant, shiny as new, has beautiful patterns, elegant and durable colors, good stability, and small deformation. - Walnut

It is distributed in the eastern regions of the United States, but the main commercial forest areas are located in the central states. Walnut wood is usually straight wood grain but also has wavy or curved wood grain, producing attractive and decorative figures. Walnut is a kind of medium-density tough hardwood with moderate bending strength and breaking strength. It is also the most durable wood. It can be used for furniture, cabinet manufacturing, interior building structure, high-grade joinery products, doors, floors, and panels. It is a good wood used together with light-colored wood to produce a contrast effect.

It is distributed in the eastern regions of the United States, but the main commercial forest areas are located in the central states. Walnut wood is usually straight wood grain but also has wavy or curved wood grain, producing attractive and decorative figures. Walnut is a kind of medium-density tough hardwood with moderate bending strength and breaking strength. It is also the most durable wood. It can be used for furniture, cabinet manufacturing, interior building structure, high-grade joinery products, doors, floors, and panels. It is a good wood used together with light-colored wood to produce a contrast effect. - Red Oak

It is widely distributed in the eastern parts of the United States. The appearance of red oak is usually similar to that of white oak, but there are few visible figures due to the finer ray of pith. Most of the red oak is straight grain with rough texture. Red oak gets its name because its leaves turn red in autumn. Good surface can be obtained after dyeing and polishing. Red oak is hard and heavy, with medium bending strength and rigidity.

It is widely distributed in the eastern parts of the United States. The appearance of red oak is usually similar to that of white oak, but there are few visible figures due to the finer ray of pith. Most of the red oak is straight grain with rough texture. Red oak gets its name because its leaves turn red in autumn. Good surface can be obtained after dyeing and polishing. Red oak is hard and heavy, with medium bending strength and rigidity. - White Oak

It is widely distributed in the eastern parts of the United States. The white oak is mostly straight-grained, with medium to rough texture. The pith ray is longer than the red oak, so the white oak has more shapes. White oak is hard and heavy, with medium bending strength and poor rigidity. The heartwood has corrosion resistance, and it is extremely difficult to penetrate the anti-corrosion treatment agent. White oak has medium resistance to the penetration of the anti-corrosion treatment agent.

It is widely distributed in the eastern parts of the United States. The white oak is mostly straight-grained, with medium to rough texture. The pith ray is longer than the red oak, so the white oak has more shapes. White oak is hard and heavy, with medium bending strength and poor rigidity. The heartwood has corrosion resistance, and it is extremely difficult to penetrate the anti-corrosion treatment agent. White oak has medium resistance to the penetration of the anti-corrosion treatment agent. - Hard Maple

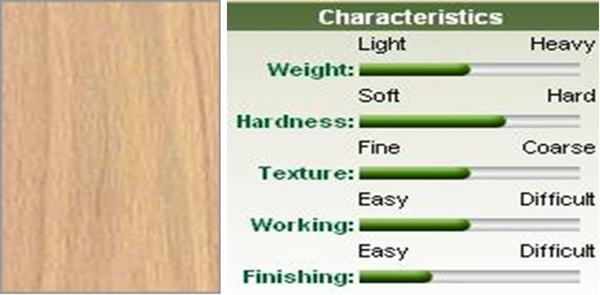

It is mainly produced in the eastern United States, mainly distributed in Central Atlanta and Lake. It has a dense and fine texture, usually straight wood grain, but also curved, bow backed, and birds eye wood grain. Hard maple wood is hard and heavy, with good strength, especially high abrasion resistance and abrasion resistance, and also good steam bending resistance.

It is mainly produced in the eastern United States, mainly distributed in Central Atlanta and Lake. It has a dense and fine texture, usually straight wood grain, but also curved, bow backed, and birds eye wood grain. Hard maple wood is hard and heavy, with good strength, especially high abrasion resistance and abrasion resistance, and also good steam bending resistance. - Soft Maple

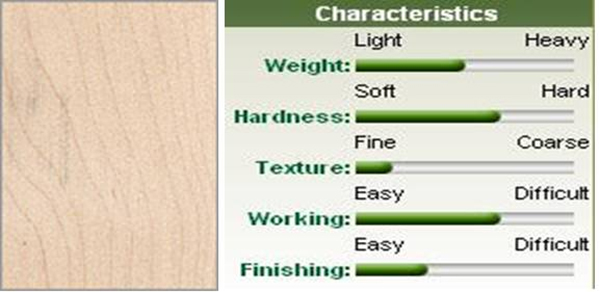

It is mainly produced in the eastern parts of the United States but less in the west bank (Acer truncatum). Most properties of soft maple are very similar to hard maple. Although soft maple is widely distributed, its wood color varies greatly with different habitats. The hardness of soft maple is about 25% less than that of hard maple. It has medium bending and breaking strength, low rigidity, and seismic strength, and good steam bending resistance. No resistance to corrosion and insect erosion. Soft maple is often used as a substitute for hard maple or dyed to imitate other wood (such as cherry wood). Its physical properties and processing properties also make it a substitute for beech wood.

It is mainly produced in the eastern parts of the United States but less in the west bank (Acer truncatum). Most properties of soft maple are very similar to hard maple. Although soft maple is widely distributed, its wood color varies greatly with different habitats. The hardness of soft maple is about 25% less than that of hard maple. It has medium bending and breaking strength, low rigidity, and seismic strength, and good steam bending resistance. No resistance to corrosion and insect erosion. Soft maple is often used as a substitute for hard maple or dyed to imitate other wood (such as cherry wood). Its physical properties and processing properties also make it a substitute for beech wood. - Beech

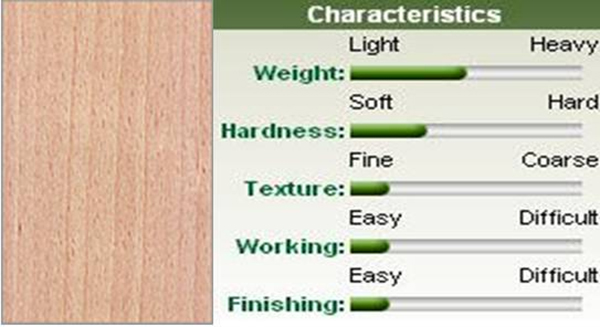

It is produced all over Europe Compared with European beech, the color of American beech is slightly darker, and the consistency is slightly poor. This kind of wood is usually straight grain, with a tight and uniform texture, and can be dyed and polished to obtain a good surface. Drying is fast, but warping, cracking, and surface cracks very easy to occur. Large shrinkage and moderate performance change. American beech is a kind of heavy, hard, strong, earthquake-resistant wood that is very suitable for steam bending.

It is produced all over Europe Compared with European beech, the color of American beech is slightly darker, and the consistency is slightly poor. This kind of wood is usually straight grain, with a tight and uniform texture, and can be dyed and polished to obtain a good surface. Drying is fast, but warping, cracking, and surface cracks very easy to occur. Large shrinkage and moderate performance change. American beech is a kind of heavy, hard, strong, earthquake-resistant wood that is very suitable for steam bending. - Mahogany

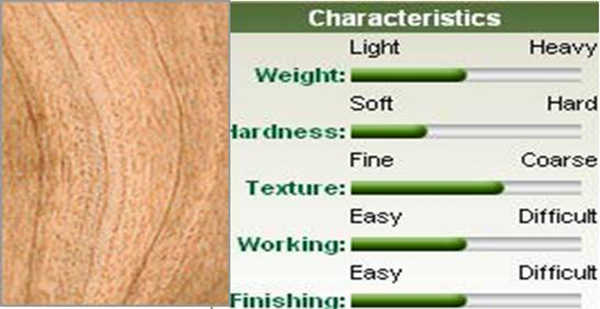

It is produced in Indonesia, Cuba, Brazil, Central America, and Africa. It has an oblique texture, dense and uniform material, moderate hardness, and easy carving. The heartwood changes from light reddish brown to dark reddish brown, so it is called mahogany. It is the main material for high-grade furniture at present. The wood grain is very beautiful, and the longer, the better the luster. Because the wood is delicate and high in hardness, it can be used to carve various shapes. Its service life can be as long as hundreds of years. In the famous noble families in Europe, you can often see the trace of mahogany.

It is produced in Indonesia, Cuba, Brazil, Central America, and Africa. It has an oblique texture, dense and uniform material, moderate hardness, and easy carving. The heartwood changes from light reddish brown to dark reddish brown, so it is called mahogany. It is the main material for high-grade furniture at present. The wood grain is very beautiful, and the longer, the better the luster. Because the wood is delicate and high in hardness, it can be used to carve various shapes. Its service life can be as long as hundreds of years. In the famous noble families in Europe, you can often see the trace of mahogany.

Timber door core material:

- Finger Joint Wood:

Finger joint, as a wood connection method, has not only good connectivity but also is conducive to wood stability. Generally, the raw materials for finger joint wood are pine and china fir.

Finger joint, as a wood connection method, has not only good connectivity but also is conducive to wood stability. Generally, the raw materials for finger joint wood are pine and china fir. - Plywood/Multilayer Board:

It is a kind of man-made board. The slabs made of glued veneer in a crisscross manner in the direction of wood grain are pressed with or without heating. Three plywood and five plywood are commonly used.

It is a kind of man-made board. The slabs made of glued veneer in a crisscross manner in the direction of wood grain are pressed with or without heating. Three plywood and five plywood are commonly used. - MDF:

The artificial board is made from the thinned wood of branches, small diameter wood, fast-growing wood, bamboo and other plant materials with limited wood resources. The surface is flat and smooth for secondary processing.

The artificial board is made from the thinned wood of branches, small diameter wood, fast-growing wood, bamboo and other plant materials with limited wood resources. The surface is flat and smooth for secondary processing. - Chipboard:

It is a kind of artificial board made by pressing leftover materials and wood chips during wood processing. The structure is relatively uniform, and the processing performance is good. It can be processed into large format plates as required. The finished chipboard does not need to be dried again and can be used directly, with good sound absorption and sound insulation performance. But it also has its inherent shortcomings because the edge is rough and easy to absorb moisture; It is also heavier than other plates.

It is a kind of artificial board made by pressing leftover materials and wood chips during wood processing. The structure is relatively uniform, and the processing performance is good. It can be processed into large format plates as required. The finished chipboard does not need to be dried again and can be used directly, with good sound absorption and sound insulation performance. But it also has its inherent shortcomings because the edge is rough and easy to absorb moisture; It is also heavier than other plates. - PVC:

PVC is the abbreviation of polyvinyl chloride resin, and polyvinyl chloride is a linear thermoplastic polymer. Take PVC as the base material, and add plasticizer, stabilizer, pigment, filler, lubricant, etc. After kneading, mixing, pulling, pelleting, extruding or die-casting at a certain temperature, the plastic products are made after cooling and shaping. This product is an excellent thermoforming material that can replace some stainless steel and other corrosion-resistant synthetic materials. It is widely used in chemical, petroleum, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications, and decoration industries.

The above is some basic knowledge about timber doors. Hoping it can help you!