R&D

Our Team

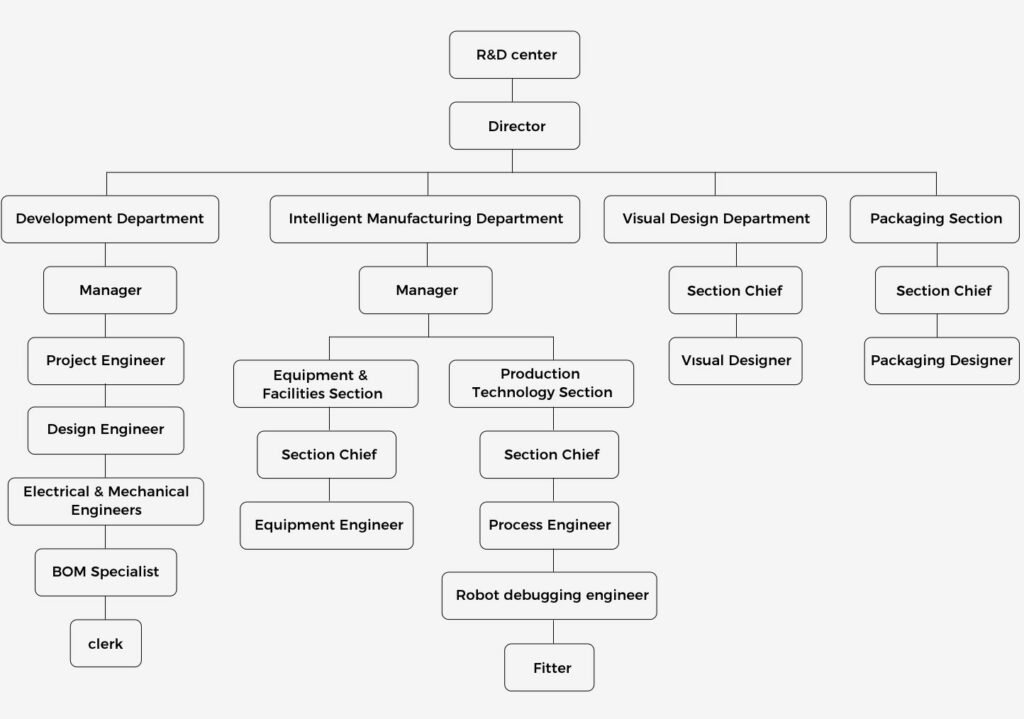

Since its establishment, the company has always adhered to the scientific concept of development, taking technology research and development and personnel training as its development goals. The R&D center currently has 33 people, a professional management team, and a technical R&D team with rich experience and strong innovation ability.

The company attaches importance to the development of new products and new processes, has invested a lot in research and development every year, and has achieved excellent results. The R&D team has obtained nearly 100 patents. In the process of product research and development, according to technological development and market demand, the company transforms research and development results into productivity through technology introduction, cooperative development, and other forms, creating benefits for the enterprise. 428 series of products have been successfully developed at present, covering sliding door system, iron frame door/window, room partition, canopy, etc. There are many fabulous products, with monthly sales of 13w sets. Furthermore,Tengyu can carry out customized product design to meet various needs of customers.

Designing Ability

P1

Product design and development

- · Voice of customers

- · market research

- · Feasibility analysis report

- · Design assignment book

- · Project book

- · Project development schedule

- · Development planning review

- · Product initial design (BOM, process, special features)

- · Cost Analysis Table

- · Feasibility assessment report

P2

Product design and development

- · Design assignment book

- · DFMEA

- · drawing

- · Product material specification

- · Product Manual

- · Calculation book

- · Experiment outline

- · Tooling design

- · Sample trial production notice

- · Manual prototype test report

P3

Product design and development

- · Process flow chart

- · Site layout

- · List of special features

- · Feature Matrix

- · PFMEA

- · Control Plan

- · Operating instructions

- · Testing standards

- · Acceptance Criteria

- · Product Manual

- · Wide range of packaging patterns

- · Name brand/logo/packing list

- · Small batch trial production notice

P4

Product process validation

- · Trial production

- · Full-size inspection report

- · Product experimental test report

- · MSA report

- · Process capability research report

- · RUN & TATE report

- · Cost confirmation

- · Product quality summary and identification

- · PPAP

P5

Mass production /Improvement

- · Customer feedback

- · Mass production notice

- · Design improvements

- · Design and development confirmation review

1. Solidify the product development process of the enterprise and realize the controllable management of the product development process.

2. The drawing documents and technical documents are first entered into the PLM system and are printed and issued through the solidified signing process and electronic signature to ensure that the on-site technical documents are consistent with the status and content in the PLM.

3. Take the process BOM as the center to realize the data exchange between materials, BOM, and the existing ERP system.

4. Solidify engineering change management to ensure the controllability and standardization of technical changes.

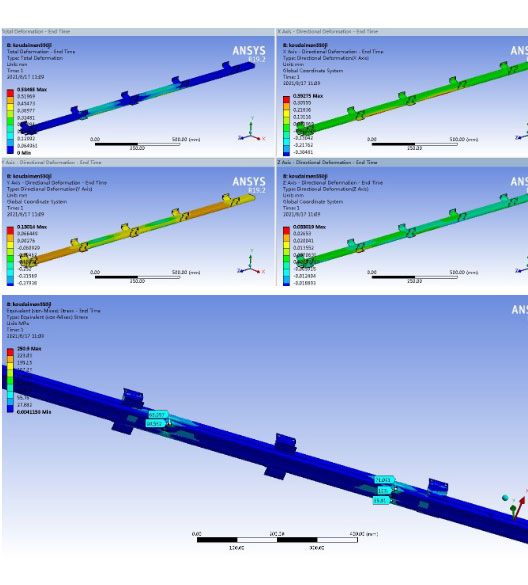

Skills of Analyze

Three-dimensional modeling of pocket door series products

Schematic diagram of finite element analysis

Test Ability

Sliding door test stand

Lock life tester